-

ORGANIC AGRICULTURE

- AGROBIOFILM

- RECTIFIER VACUUM CLEANER

- DISPOSABLE PLASTIC BOX

- HARVESTERS FOR AROMATIC AND MEDICINAL PLANTS

- UNWINDER WATERING TAPE

- MANUAL. SEEDER

- HYBRID SOLAR DRYERS FOR AROMATIC PLANTS AND FOOD

- MULTI-SEED MECHANICAL SEWER.

- BIG GRAIN SEEDER

- HEATING SYSTEMS FOR INDUSTRIAL WAREHOUSES

- SYSTEM FOR COLLECTING PARSLEY

-

ENVIRONMENT

- RAINWATER

- RETENTION BASINS

- SANITARY BOOTHS

- BATTERY CASES

- SAMPLING BOX

- SCREENING BOX

- TANKS FOR INDUSTRIAL CLEANING

- TOOLS BOX

- SELECTIVE COLLECTION CONTAINER

- TANKS WITH LIDS DCT

- DOSING TANKS DSD

- HORIZONTAL TANKS DHE

- HORIZONTAIS TANKS DHS

- VERTICAL TANKS DVA/DVB/DVBR

- ECOFLO-COCONUT COMPACT FILTER

- ECOIL-USED OILS TANKS

- ECOPROCESS TM

- PUMPING STATIONS

- SEPTIC TANKS MILENIUM

- COMPACT SEPTIC TANKS

- SIMPLE SEPTIC TANKS

- MICRO-ETAR SOLIDO SMART

- BEACH CLEANING MACHINE

- GREASE SEPARATOR

- HYDROCARBON SEPARATORS

- SUPERFUSTO

- DRUM SUPPORT

- INDUSTRIAL SCALE

- PUMPS FOR FUELS

- CONTENTOR - OFICINA

- DIESEL DEPOSIT

- WEEDING THERMAL ECO

- WASHING EQUIPMENT

- FORAGER EQUIPMENT

- FRUTICULTURE

- DRY FRUITS

- GPS AGRICOLAS

-

HORTICULTURE

- FERTILIZER LOCATOR

- BED FORMER AND PLASTIC FIXER

- ROTATING CULTIVATOR

- POTATO DIGGERS

- RECTIFIER VACUUM CLEANER.

- POTATOS LOADER

- CARROT HARVESTER

- ONION LOADER

- CITRUS HARVESTER

- DISPOSABLE PLASTIC BOX..

- VEGETABLE HARVESTER DI PIETRI

- VEGETABLE HARVESTERS ORTOMEC

- VEGETABLES HARVESTER

- GARLIC CULTURE

- PLASTIC DISPENSERS MACHINE

- SOIL DISINFECTION BY STEAM

- FURROW OPENER

- KITAPE

- FLAME WEEDING

- MULTIFRAS

- POTATO PLANTER

- PRE-BED FORMER

- MACHINE FOR COLLECTION IRRIGATION HOSE

- RECOLHEDORA DE PLÁSTICO AGRICOLA

- AUTOMATIC HOE

- WEEDING MACHINES

- SYSTEM FOR COLLECTING PARSLEY.

- TRANSPLANTERS

- SIDE CONVEYOR BELT

- MOBILIZATION OF SOIL

- LIVESTOCK

- POLISHER

- SPRAYERS

- SOWING

-

FORESTRY

- ANGLODOZERS

- GARDEN VACUUM CLEANERS

- HEDGE MOWING BAR

- BIOSHREDDERS

- BULDOZERS

- HYDRAULIC HEADS

- ROTARY CUTTERS

- LAWN MOWER

- BULLRING CUTTER

- TRIMMER

- FURROW OPENER RIENFORCED.

- MOUND MACHINE FOR ORCHARDS.

- DISC HARROWS V-TYPE

- FORESTRY WINCHES

- POST HOLE DIGGER

- TOOL HOLDERS ER

- SHOVEL GRADERS

- PRUNERS FOR ORCHARDS

- RIPPERS

- BRUSH CUTTERS

- WOOD-SPLITTERS

- BLADE ROLLER.

- ROTARY TILLERS BY RADIO CONTROL

- HYDRAULIC ARM IRONER

- TRACTOR BACKHOE

- SHREDDERS AGRIMASTER

- ROTARY TILLERS JOPER.

- FORESTRY SHREDDERS

- CRUSHERS RINIERI

- ROTARY TILLERS HERKULIS

- CRUSHERS FOR BIOMASS

- STONE MILLS

- STRAINERS SERRAT LATERALS

- VINEYARDS REMAINS FROM PRUNING

- CRUSHERS SERRAT

- IRRIGATION SYSTEMS

- AGRO CONTROL SYSTEMS

- SCISSORS FOR PRUNING.

- TRANSPORT

- FLORICULTURAL NURSING

-

GRAPE VINE

- BOXES STAINLESS FOR GRAPE

- PLASTIC BOXES STACKABLE

- ELECTRICAL TROLLEY

- WIRE UNWINDERS

- FEEDING BUCKET

- MANURE SPREADERS

- VINEYARD DISC HARROWS

- OFFSET MACHINERY

- ELECTRIC TYING MACHINE FOR GRAPEVINE

- HITTING STAKES HAMMER

- POST HOLE DIGGER.

- ROLLER HARROW VINEYARD

- TOWING OF INOX FOR GRAPE.

- SCISSORS FOR PRUNING

- VINE AND TREES PLANTER

- TOWED VINDILLER

- PRUNING REST CRUSHER

- CHISEL VINHATEIRO

- SPARE PARTS

- USED MACHINES

- ABBRIATA

- ABRIMEC

- AGRATOR

- AGRICOLA ITALIANA

- AGRIMASTER

- AGROBIOFILM

- AGROGUIA

- AGROOP

- AGROTECH

- AMB ROUSSET

- ARGILES

- ASPLA

- BARGAM

- BBKW

- BONDIOLI & PAVESI

- BONINO

- CACHAPUZ

- CAEB

- CARLOTTI G. & C. S.N.C.

- CECCATO OLINDO

- CETAP

- CHECCHI & MAGLI

- CITERGAZ

- COMEB

- D'EUSANIO

- DAGNAUD

- DI PIETRI

- DONDI

- EAZYCUT

- ENOROSSI

- ENRIA

- F. LLi. ANNOVI

- FAE

- FARDIN

- FELCO

- FERRARI

- FEUCHT - OBSTTECHNIK

- FIALHO

- FIMAKS

- FMP

- Farmi

- GARRIGA

- GASPARDO

- GIAMPI

- GREEN-TECHNIK

- HERKULIS

- HYMACH

- ID-DAVID

- IMAC

- IRRILAND

- J.J.BROCH

- JB INDUSTRIE

- JOPER

- M.MARTI

- MAIA

- MAMMUT

- MARTIGNANI

- MM SPRAY

- MOSA GREEN

- MTS.SANDEI

- NASI

- OLITREE

- OLIVERAGRO

- OMARV

- ORTOMEC

- PAGLIARI

- PELLENC

- PIRODISERBO

- PIUSI

- POMI

- PREMIER TECH

- R.A.P

- REBOAL

- RIBATEJO

- RINIERI

- ROCHE

- SERRAT

- SIMON

- SIMOX

- TAREX

- TATU

- TERRADONIS

- TERRATECK

- TEYME

- TOMENZOLI

- TOMIX

- TOUPEIRA

- TRIMBLE

- VALENTINI

- WAGNER

SOIL DISINFECTION BY WATER VAPOR, SIMOX AGRIVAP 2010, ELECTRIC AUTOMOTIVE

-

Categories::

-

Brands:SIMOX

- Available by order

-

SKU::AGRIVAP2010E

-

PDF catalog:Gerador de vapor de baixa pressão SIMOX AGRIVAP 2010 PT.pdf

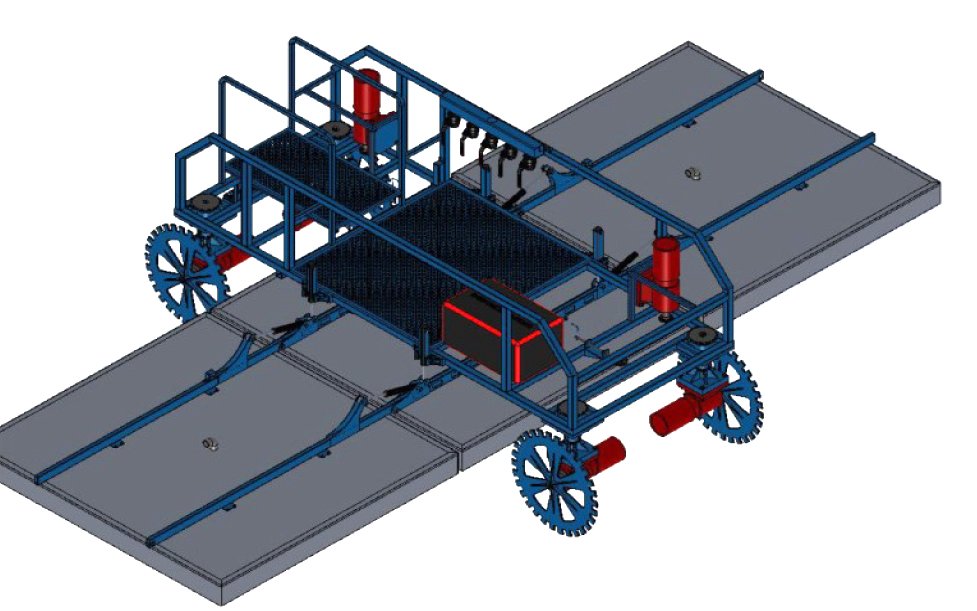

AGRICULTURAL SOIL DISINFECTION SYSTEM USING WATER VAPOR, SIMOX AGRIVAP 2010 WITH ALUMINUM CAMPANULES AND ELECTRIC AUTOMOTIVE DISPLACEMENT

Why use low-pressure steam?

On agriculture for disinfecting ground soil without using chemical products, especially in organic and responsible farming, farmer’s market gardening, seedling nurseries, greenhouses, horticulture, agronomic research institutes, compost preparation.

Gerador de vapor de baixa pressão SIMOX Tipo AGRIVAP "2010 CE"

Code No: 19954552

Steam production: 1,000 KG-Steam/hour

Steam temperature: 195 - 210°C

Heating power: 785 KW

Heating power: 675,000 KCAL/hour

Base Machine

Composed by:

- 1 Automatic Burner: Weishaupt:WML10-4-EXT

3 Stages - 400 V-Tri

FOD consumption: 71.5 kg/h (i.e. 85.8 l/h)

- 1 burner steel protective cover

- 1 New generation heat exchangers

- 1 Filter (domestic fuel oil) to protect the burner from clogging

- 1 Water level regulator with stainless steel electrodes (5), with bottle-type water

shortage safety device.

- 1 Water level sight glass: Pyrex porthole - Ø 70 mm.

- 1 Burner control pressure switch - cut at 0.5 bar

- 2 2nd and 3rd speed switches - Power regulation at 0.38 and 0.42 bar

- 1 control box including: 1 main switch

1 Burner on/off switch 2 Water level control relay 1 1 "Power on" indicator light

- 1 Water supply solenoid valve: 209/20/MG – 3/4- Mono. 220 V. with filter, nonreturn valve and Express 3/4

connection

- 1 steam pressure gauge: 0/1 bar - Ø 100 mm - STAINLESS STEEL

- 1 "Sunstroke" safety device by thermostat: RAK ST 1300 P

- 2 bronze safety valves: 1-1/2" with discharge tube

- 3 Drain valves - Steam B/S - full passage

- 5 Inspection and descaling hatches in the heating body

- 2 hinged pre-heater openings, giving access to the inside of the machine on both sides

- 1 Steam super heater for steam at 195-200°C

- 1 Chimney - Ø 342 mm and chimney cover

- 1 Double steam outlet with T: 3" - F. with 2 valves in DN80 and 2 male SIAMEC D89 connectors

- 1.600 liter fuel tank installed on the chassis -

- 1 sacrificial anode to protect the boiler against corrosion caused by aggressive water

with very low resistivity (less than 2,500 ohms/cm).

- 1 Insulation of the central heating body

- 1 mobile chassis with two wheels: 10.0/75-15.3-10PR-AW909 + 1 foot + 1 swivel frame

- 1 Reel with electric cable 5 x1.5 of 50 meters

Electric self-propelled chassis with Aluminiun campanules

No. Code: 19954570

1 Electric self-propelled structure with bells type SAE 2010, with:

1 Chassis complete with support for mounting hoods

1 Steam distributor equipped with 3 D50 outlets and 3 male valves and Siamec D89 inlet.

Steam distribution by 3 D50 steam pipes.

1 Hydraulic lifting system for hoods driven by a hydraulic pump and manually controlled by a

selector:

1 Chassis for fixing 3 hoods for a work surface of 2666 x 7500 mm.

1 Hydraulic lifting of hoods.

4 D800 ep10 mm metallic wheels each with 380 V geared motor, controlled by a PLC for synchronization of

advance (Advance time from 4 to 6 seconds) – Set track 1500 mm.

1 Front and rear steering system that allows 180° steering of the wheels by pinion / rack and hydraulic movement, manually

controlled by a selector. This system will allow lateral movements, by chosen angle or

to make machine rotations.

1 3-Point Single Side Transport Hitch - Two jockey wheels or equivalent.

1 Electric cable reel in 5 x 1.5 of 50 meters

1 400 V power supply - three-phase

Simox water treatment unit

No. Code 19954592

1 Water treatment unit, with:

1 Cartridge filter - Elimination of MES to protect the water softener

1 Duplex volumetric descaler 2x30 liters

1 Automatic dosing unit for product injection. 1 Set mounted on the generator frame

1 Commissioning of the treatment system - Not included 1 Training of operating personnel - Not included

Consumables: 1st load not included

1 Consumables: 1st charge for water treatment:

2 bags of salt: 2x 25 kg = 50 kg

1 Consumables: 1st charge for water treatment:

Dosing product PH –SOLUVAP 419: 75Kg i.e. 3 cans of 25 Kg

Test equipment for monitoring water treatment setups including:

1 TH water test kit ref 1KT001

1 test kit for sulphites in water ref 1KS003

2 - Water treatment system

Steam generators - Type AGRIVAP bear the "CE" marking, in application of the directives of the

following European countries:

Machinery Directive 2006/42/EC: Low

Voltage Directive 2006/95/EC

Electromagnetic Compatibility Directive 2004/108/

Soil disinfection

With SIMOX low-pressure steam generators, the principal is to bring the ground to a temperature high enough to destroy a maximum amount of parasites and weeds while respecting the micro organisms useful for cultivation.

Why use low-pressures steam for disinfecting ground soil, but also for disinfecting the substratum like planting soil and composts?

Polyvalent, quick and effective: insects, larvae and particularly pathogenic seeds of cryptogamic diseases are destroyed. The low-pressure steam is extremely efficient, contrary to selective chemical products. Here are several uses for the disinfecting of ground soil using low-pressure steam generators:

- Weed-killing treatment

- Fungicidal treatment

- Nematicidal treatment

- Insectidal treatment

- Anti-viral treatment

A healthy and natural method: no toxic residue left in the ground, nor in the harvested products, disinfecting the ground soil with steam plays an important role in the fight against pollution and the return to an improved biological balance.

It is possible to plant new seeds immediately at the end of the steam disinfecting process.

Advantages and benefits on the ground soil from the heat treatment:

- Improved assimilation of elements by the soil.

- Respect for bacterial activity, as the temperature does not go above 90°C.

Effects on the germination, favorable actions on the health and balance of the plants:

- More developed root systems

- Higher level of chlorophyll

- Regularity and luxuriance of the vegetation

100% weed-killing: Roots and seeds of the weeds are scorched thanks to the steam vapor. Weeds are eliminated.

19954552

TOWED LOW PRESSURE STEAM GENERATOR BRAND: SIMOX MODEL: AGRIVAP 2010 CE/ 1000 KG STEAM/HOUR

19954570

AUTOMOTIVE CHASSIS ELECTRICALLY DRIVEN BY A MOTOGENERATOR, EQUIPPED WITH 4 DRIVE WHEELS ROTATING AT 180º EQUIPPED WITH 3 ALUMINUM CAMPOLES FOR A TOTAL WORKING WIDTH OF 7.50 M + 30 M STEAM TUBE BRAND: SIMOX MODEL: SAE 2010 7500X2666 MM

19954758

20 M TUBE KIT FOR D.80 WATER VAPOR WITH 2 SIAMEC COUPLINGS BRAND: SIMOX MODEL: FOR AGRIVAP 2010 CE

19954554

EXTENSION OF THE 20 M WATER STEAM TUBE WITH MALE COUPLING D.80 AND FEMALE COUPLING D.89 BRAND: SIMOX MODEL: MALE D.80/FEMALE D.89 - 10 M TUBE

Optional Equipment:

19954592

COMPLETE EQUIPMENT FOR WATER TREATMENT WITH 1 CONSUMABLES KIT BRAND: SIMOX MODEL: P/ AGRIVAP 2010

DEADLINE:

UP TO 90 DAYS AFTER ORDER CONFIRMATION